| Payment Type: | T/T,Money Gram,Western Union |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 15 Days |

Basic Info

Model No.: MCKS-130

Condition: New

Certification: ISO, CE, CE ISO

Automation: Automatic

Screw: Other

Treatment: Other

Item: Sludge Carbonization Treatment Dry Distillation Furnace

Type: Refuse Collector

Warranty: 2 Years

Application: Sludge Carbonization Dry Distillation

Capacity: 100-800T/H

Function: Municipal Solid Waste Sorting

Voltage: 200-480)V(customizable)

Power: 220V/380V

Usage: Waste Treating

Additional Info

Packaging: standard export package

Brand: MeCan

Transportation: Ocean,Land,Air

Place of Origin: China (Mainland)

Supply Ability: 100 sets per month

Certificate: CE ISO

Port: Guangzhou

Product Description

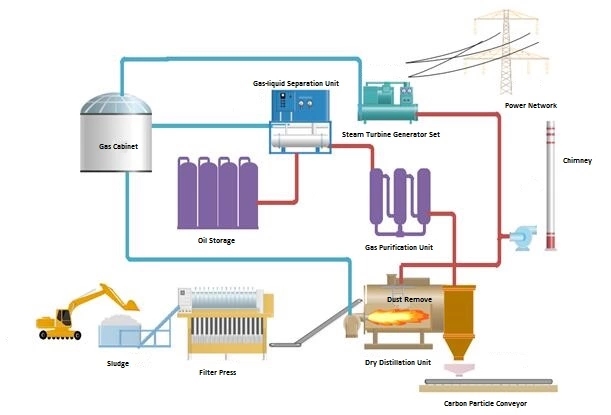

The sludge carbonization treatment can continuous operation, simple operation management, accessory equipment, thus make less investment, labor, energy consumption and maintenance costs are lower, at home and abroad in the sludge dewatering, widely used in domestic development especially rapidly in China at present, new cities sewage treatment plant, enterprise of sewage treatment dewatering equipment are adopted almost belt type sludge dehydrator.

Diameter: 1.5m – 3.6m

Length: 4m – 45m

Capacity: 12-4000T/D

Process description

S.N.

Name Spec.Mode

Heating Method

Heating Temperature

Production mode

Processing capacity

(t/h)

1

Pyrolytic furnace

Indirect Heating

400~600

Continuous type

1.5~5

2

Carbonization Rotary Kiln

Indirect + direct heating

400~650

Continuous type

3~15

The preparation of biochar from sludge by dry distillation is a chemical reaction under closed, anaerobic and high temperature conditions. The sludge is thermally decomposed at high temperature to produce combustible gas and material charcoal and so on,so as to effectively decompose sludge, achieve resource utilization, protect the environment, and achieve benefits.

Technical Characteristics

1. Dry distillation is carried out under sealed, oxygen-free, non-combustion and high temperature conditions, avoiding the production of dioxins, nitrogen oxides and so on.

2. The mixture gas (steam and non-condensable combustible gas) produced in the process of sludge retorting is purified and separated, and the combustible components such as methane and ethane are used as the fuel of the retorting sludge unit.

3. Clean gas fuels such as gas are used in the treatment of sludge by dry distillation, and the tail gas produced by the fuel after combustion in the combustion chamber reaches the national standard.

4. Sludge is directly transported to the retort unit for treatment, which avoids bacterial fermentation, odor and air pollution.

5. The water vapor produced in the process of sludge treatment by dry distillation is condensed, recovered and purified to become condensate, and the condensate is recycled and discharged as cooling water.

6. The sludge treatment unit of dry distillation is equipped with dust removal equipment. In the process of dry distillation, biochar dust can be prevented from polluting the environment and protecting the working environment and health of the operators.

CONTACT US

Guangzhou MeCan Medical Limited

Address: Room 510,Yidong Mansion,No.301-303,Huanshi Middle Road,Yuexiu,Guangzhou City,Guangdong,China,Guangzhou,Guangdong

Contact Person: Joe Jiang

Phone:86-20-84835259

Fax: