| Payment Type: | T/T,Money Gram,Western Union |

|---|---|

| Min. Order: | 1 Pack/Packs |

| Delivery Time: | 15 Days |

Basic Info

Model No.: MCL-SJ1200

Certification: SGS, CE

Condition: New

Voltage: Custimized

Power(W): 10Kw-70Kw

Weight: 2t-10t

Dimension(L*W*H): Customized

Material: Stainless Steel SUS304

Control System: Fully Automatic

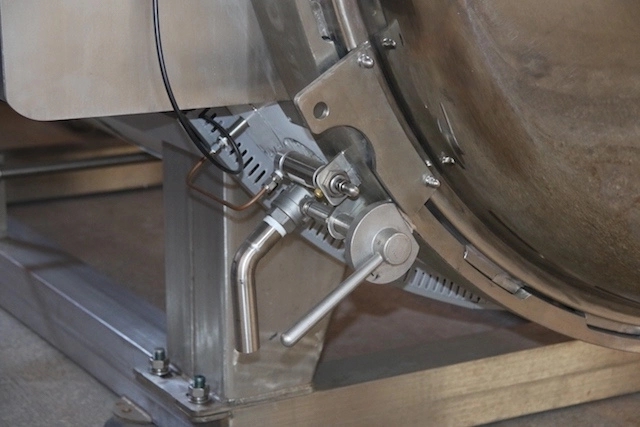

Sterilizing Way: Water Immersion

Design Temperature: 147 Degree Centigrade

Max Pressure: 0.35 Mpa

Additional Info

Packaging: standard package for export

Brand: MeCan

Transportation: Ocean,Land,Air

Place of Origin: China (Mainland)

Supply Ability: 100 sets per month

Port: Guangzhou

Product Description

The Water Immersion Process is the most widely accepted method of sterilizing product using an overpressure process. The Water Immersion process is similar to a saturated steam process in that the product is totally isolated from any influence of cooling air – the product is totally submerged in water. But, it is different from Saturated Steam in that air can be introduced into the vessel during sterilization. Overpressure is provided by introducing air (or steam) on top of the water. In some instances, air is added to the steam (which then heats the air). The heated air agitates the water as it flows to the surface and serves to pressurize the process load.

Condition:

New

Place of Origin:

Guangdong, China (Mainland)

Brand Name:

Mecan

Voltage:

Custimized

Power(W):

10Kw-70Kw

Weight:

2t-10t

Dimension(L*W*H):

customized

Certification:

ISO CE SGS

Warranty:

1 Year

After-sales Service Provided:

Field installation, commissioning and training, Engineers available to service machinery overseas

Product name:

water immersion retorts

Application:

canned food

Material:

Stainless Steel SUS304

Control system:

Fully Automatic

Sterilizing way:

Water immersion

Heating way:

Boiler Steam/electricity

Design Temperature:

147 Degree Centigrade

Max pressure:

0.35 Mpa

Advantage:

High Efficiency/big capacity

MULTI-PROCESS PILOT RETORTS

• Optional oscillating motion

• Available in static, oscillating and rotary, water immersion option

• Tests pasteurization, sterilization, and cooking of food products in any type of container

• Research and development of new products

• Simulation of new recipes and processes for existing products

• Production of small runs for market studies

Retorts are at the heart of many shelf-stable food processing lines such as:

• Milk

• Fruit Juices

• Tea, Coffee

• Soups, baby food, pet food

• Ready-meals, astronaut food

• Sauces etc.

|

Material

|

Capacity

|

Overall dimension

|

Max pressure

|

Max |

|

Ss 304

|

150 L

|

2000*1000*1800mm

|

0.35 Mpa

|

147 ℃

|

|

Install power

|

Consumption

|

Control mode

|

||

|

2 KW

|

Electricity: 1.1 Kw/batch

|

Steam: 2.5 Kg/batch

|

Process water : 80 L

|

PLC automatic

|

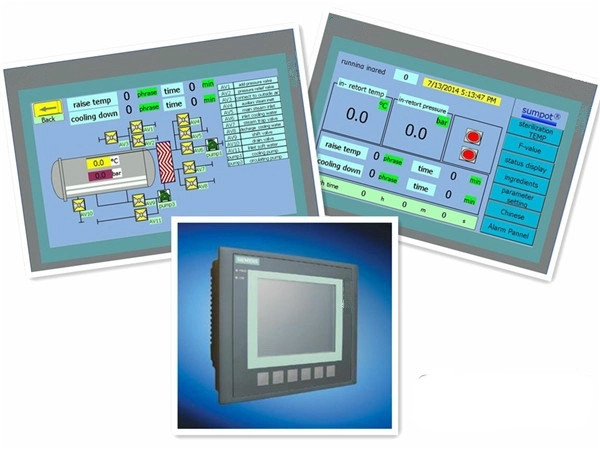

Machine Parts Touch Panel

The touch panel TP1200 is the comfortable instrument for the input and operation of the programs. The clear layout of the operating interface simplifies the operation of complicated full-immersion rotation retorts.

Digital recorder

The paperless recorders stand out through their innovative operating concept and high standards of security to prevent unauthorized access and manipulation of the stored data.

CONTACT US

Guangzhou MeCan Medical Limited

Address: Room 510,Yidong Mansion,No.301-303,Huanshi Middle Road,Yuexiu,Guangzhou City,Guangdong,China,Guangzhou,Guangdong

Contact Person: Joe Jiang

Phone:86-20-84835259

Fax: